Direct electrical drive train with wheels/caterpillars positioning precision and variable transmission

|

With maximum motor torque IntEn controller controls small shift of wheels as 0.1 mm and smaller (depending on gear ratio). Even with maximum traction because of our unique transmission, EV48 system can precisely control vehicle trajectory. |

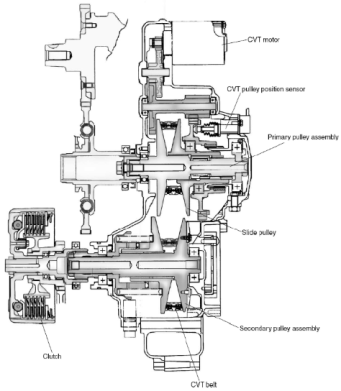

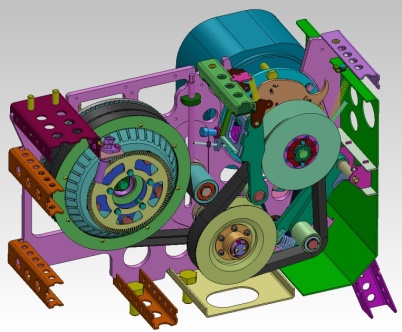

Nowadays there exist two approaches in EV architecture for high tractive force presentation: first is high voltage for motor control and the second is initial RPM running before load application. In the first case high voltage applies for wheels motors in the second CVT appears in the architecture. High voltage means danger for life and is inappropriate for moisture conditions. CVT consists of driving pulley and clutch pulley. The idea of CVT operation is clutching of belt when engine gets some RPMs that means friction of belt by clutch when load is applied. Modern CVT belts have long life time and CVT is more or less reliable. Almost all modern CVTs have electronic control of clutch extending belt life time. The CVT is used in low cost transmissions where torque of one low voltage motor is distributed by transmission between wheels (as usual by differential between two rear wheels). Using of CVTs with clutch separately for each drivetrain wheel is impossible, because of belt clutch unproductiveness moment. Using of classical CVTs can’t provide torque synchronization of different wheels. ASYSD CVT doesn’t have such problem and belt is permanently clutched, because IntEn controller can provide maximum torque with zero RPM. Also encoders both on drive pulley and on clutch pulley provide precise control of gear ratio.